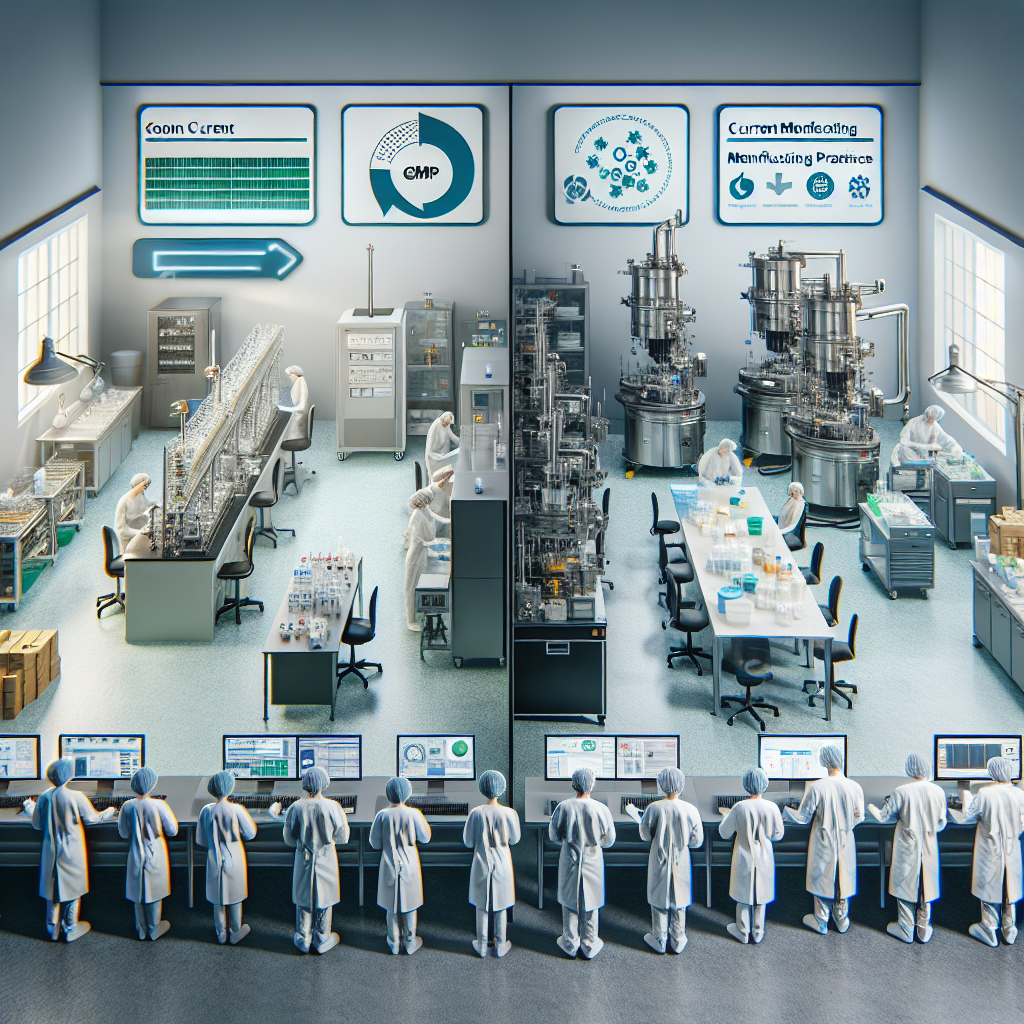

In an industry flooded with promises of health benefits and miraculous results, how can consumers truly know what they’re putting into their bodies? The answer lies in three simple letters that make a world of difference: cGMP. Current Good Manufacturing Practice (cGMP) certification stands as the gold standard for quality assurance in the supplement industry, yet many manufacturers prefer to keep its importance in the shadows.

For forward-thinking supplement manufacturers committed to excellence, cGMP certification isn’t just another acronym—it’s the backbone of product integrity and consumer trust. This certification process, overseen by the FDA, ensures that dietary supplements are produced according to stringent quality standards that cover everything from raw material sourcing to finished product testing.

The Foundation of Quality: Understanding cGMP Certification

The FDA’s regulations under 21 CFR Part 111 specifically address dietary supplements, covering the entire lifecycle of a product from manufacture and packaging to labeling, storage, and distribution. These regulations weren’t created arbitrarily—they evolved from decades of experience and represent the minimum requirements necessary to protect public health.

What sets cGMP apart from other quality indicators is its focus on process rather than just end-product testing. While testing finished products is important, cGMP certification ensures quality is built into every step of production, significantly reducing the risk of contamination, adulteration, or mislabeling.

For nutritional product developers and health-conscious manufacturers, understanding that cGMP certification isn’t optional but essential marks the difference between industry leaders and those simply trying to capitalize on market trends.

The Essential Components of cGMP: Building Quality From the Ground Up

Manufacturing Processes

At the heart of cGMP compliance are well-defined, documented manufacturing processes. These include detailed step-by-step procedures for production that minimize the risk of cross-contamination or errors. Equipment must be properly calibrated, maintained, and validated to ensure it performs as expected every time.

A supplement manufacturer with proper cGMP certification will have comprehensive records of each production batch, allowing for complete traceability if issues arise. This level of documentation might seem excessive to some, but it’s precisely what allows for consistent quality control and prompt corrective action when needed.

Quality Control Measures

Quality control under cGMP doesn’t begin at the final testing stage—it’s integrated throughout the entire production process. This includes:

– Testing of incoming raw materials before they enter production

- In-process testing at critical control points

- Finished product testing to verify specifications are met

- Stability testing to ensure product integrity throughout its shelf life

These layers of testing create multiple checkpoints to catch potential issues before products reach consumers. For enterprise businesses requiring strategic ingredient partnerships, this level of quality assurance is non-negotiable.

Packaging, Labeling, Storage, and Distribution

cGMP certification extends beyond production to encompass packaging, labeling, storage, and distribution practices. Proper packaging materials must be used to maintain product integrity, while labels must accurately reflect contents and avoid misleading claims.

Storage facilities must maintain appropriate environmental conditions, with systems in place to monitor temperature, humidity, and other factors that could affect product quality. Distribution channels must similarly protect product integrity all the way to the consumer.

For small businesses and R&D companies in the supplement space, understanding these comprehensive requirements highlights why partnering with cGMP-certified suppliers is crucial for building credible, high-quality products.

The Path to cGMP Certification: A Commitment to Excellence

Achieving cGMP certification isn’t a one-time effort but a continuous commitment to quality. For manufacturers serious about meeting these standards, the journey involves several key steps:

1. Assessing Current Practices

The first step toward certification involves a thorough gap analysis comparing current operations against cGMP requirements. This assessment often reveals areas needing improvement that might otherwise go unnoticed.

“Many manufacturers are surprised by what they discover during their initial assessment,” says a leading cGMP consultant. “Systems that seemed adequate often fall short when measured against FDA expectations.”

2. Developing Standard Operating Procedures (SOPs)

cGMP compliance requires detailed, written SOPs for every aspect of production. These documents serve as the foundation for training, consistency, and continuous improvement. They must be clear, comprehensive, and accessible to all relevant personnel.

Effective SOPs cover everything from personnel hygiene requirements to equipment cleaning protocols, material handling procedures, and quality control testing methods. They represent the institutional knowledge that ensures consistency regardless of who performs a given task.

3. Training Staff

Even the best procedures are ineffective if staff aren’t properly trained to follow them. cGMP certification requires documented training programs that ensure all personnel understand not just what to do, but why it matters.

This training must be ongoing, with regular refreshers and updates as procedures evolve. Staff must demonstrate competency before working independently, and their performance must be periodically evaluated to ensure standards are maintained.

4. Continuous Improvement

Perhaps the most important aspect of cGMP certification is the commitment to continuous improvement. The “Current” in Current Good Manufacturing Practice emphasizes that standards evolve as technology and understanding advance.

Manufacturers must regularly review their systems, incorporate feedback from audits and inspections, and proactively update processes to reflect industry best practices. This culture of improvement distinguishes truly quality-focused companies from those merely seeking to check a regulatory box.

The Rewards of cGMP Certification: Beyond Compliance

Enhanced Consumer Trust

In today’s information age, consumers are increasingly savvy about the products they put into their bodies. cGMP certification provides objective evidence of a manufacturer’s commitment to quality, building trust that no marketing campaign can achieve.

This trust translates into brand loyalty, positive reviews, and word-of-mouth recommendations that are invaluable in the competitive supplement market. As one industry leader noted, “Quality isn’t expensive—it’s priceless when it comes to building consumer confidence.”

Reduced Legal Risks

The supplement industry faces increasing scrutiny from regulators and consumer advocacy groups. Manufacturers without proper cGMP certification expose themselves to significant legal risks, including product recalls, regulatory actions, and consumer lawsuits.

The cost of addressing these issues far exceeds the investment required for proper compliance. Beyond the direct financial impact, the reputational damage from quality problems can take years to overcome—if recovery is possible at all.

Competitive Advantage

In a crowded marketplace, cGMP certification creates meaningful differentiation. It allows manufacturers to partner with premium brands that demand quality assurance, opens doors to international markets with strict regulatory requirements, and supports premium positioning that can command higher prices.

This advantage aligns perfectly with NutraAeon’s philosophy of quality, transparency, and empowerment. By providing premium ingredients that meet or exceed cGMP requirements, NutraAeon empowers partners to achieve excellence in their finished products.

NutraAeon: A Partner in cGMP Excellence

Our commitment to transparency means providing complete documentation, certificates of analysis, and full supply chain visibility for every ingredient we supply. This level of openness not only supports your cGMP compliance but also demonstrates our shared commitment to product integrity.

As a global nutritional ingredients partner, NutraAeon empowers manufacturers through technical expertise and regulatory guidance that helps navigate the complexities of cGMP requirements. We believe that quality isn’t just about meeting standards—it’s about exceeding expectations at every opportunity.

The Future of Quality: Embracing cGMP as a Strategic Advantage

As consumer awareness and regulatory oversight continue to increase, cGMP certification will become even more critical for success in the supplement industry. Manufacturers who view these requirements as obstacles rather than opportunities risk being left behind.

The hidden truth that some manufacturers don’t want you to know is that cGMP certification isn’t just about compliance—it’s about building a sustainable competitive advantage through verifiable quality. In an industry where claims are plentiful but evidence is often scarce, cGMP certification provides objective proof of a manufacturer’s commitment to excellence.

For nutritional product developers and health-conscious manufacturers looking to stand out in a crowded marketplace, embracing cGMP standards offers a clear path forward. By partnering with quality-focused ingredient suppliers like NutraAeon, these companies can build products that not only meet regulatory requirements but truly deliver on their promises to consumers.

The choice is clear: continue with minimum compliance and hope for the best, or embrace cGMP certification as a strategic tool for building consumer trust, reducing risks, and achieving sustainable growth. The most successful supplement brands have already made their decision—have you?