Every morning, millions of people reach for their B complex supplements, trusting that each capsule or tablet contains the nutrients promised on the label. But here’s a question that keeps quality-conscious manufacturers up at night: Are those vitamins still as potent as they were the day they left the production facility?

B complex vitamins play a fundamental role in human health. These eight water-soluble vitamins—thiamine (B1), riboflavin (B2), niacin (B3), pantothenic acid (B5), pyridoxine (B6), biotin (B7), folate (B9), and cobalamin (B12)—work together to support energy production, cellular metabolism, nervous system function, and DNA synthesis. They’re not just nice-to-have nutrients. They’re essential for converting the food we eat into usable energy, maintaining cognitive function, and supporting cardiovascular health.

The challenge? Getting these delicate molecules from a manufacturing facility to consumers while maintaining their full potency is far more complex than most people realize. For supplement manufacturers, this represents one of the most significant technical hurdles in product development. The difference between a high-quality B complex supplement and one that disappoints consumers often comes down to how well manufacturers understand and address the inherent instability of these vital nutrients.

The Fragile Nature of B Vitamins

B vitamins are remarkably sensitive compounds. Unlike minerals that remain stable under most conditions, B vitamins can degrade when exposed to factors that are nearly impossible to avoid during manufacturing, storage, and distribution.

Heat presents the first major challenge. During manufacturing processes like granulation, compression, or encapsulation, temperatures can rise enough to begin degrading certain B vitamins. This is why rigorous vitamin stability testing throughout the production process is essential. Vitamin B1 starts losing potency at temperatures above 100°C, while vitamin B2 begins to degrade at even lower temperatures when moisture is present. The 15-step synthesis process that early manufacturers like Merck developed for thiamine production highlighted just how challenging it is to work with these compounds—and that was just to create the raw material, not formulate it into a stable finished product.

Light exposure creates another layer of complexity. Riboflavin (B2) is particularly photosensitive, breaking down when exposed to UV light or even bright indoor lighting. This is why high-quality B complex manufacturers must carefully consider packaging materials, storage conditions, and even the lighting in production facilities. Research on vitamin B2 encapsulation has shown that its light sensitivity and poor water solubility represent major barriers to maintaining potency—challenges that require innovative solutions beyond simply keeping bottles in dark places.

pH levels add yet another variable to the stability equation. The human digestive system spans a wide pH range, from highly acidic in the stomach to alkaline in the small intestine. B vitamins must survive this journey while remaining bioavailable. Some B vitamins, like folic acid, are relatively stable at neutral pH but can degrade rapidly in acidic conditions. Others behave differently. This pH sensitivity doesn’t just affect bioavailability—it also influences how formulations must be designed, what excipients can be used, and how products should be stored.

When these factors combine—and they often do—degradation accelerates. A B complex tablet sitting on a warm shelf under fluorescent lighting in a humid environment faces multiple simultaneous threats to its potency. The reality is that many products lose significant potency before consumers ever open the bottle.

Bioavailability: The Hidden Challenge

Even when B vitamins maintain their chemical integrity, they don’t automatically deliver their benefits. Bioavailability—the proportion of a nutrient that actually gets absorbed and utilized by the body—represents a critical but often overlooked aspect of B complex formulation.

Water solubility, ironically, presents challenges despite B vitamins being classified as water-soluble. Poor solubility in gastric fluids can significantly limit absorption rates. Recent studies on vitamin encapsulation technology have confirmed that poor water solubility remains a major barrier to effective delivery. When a vitamin doesn’t dissolve properly in the digestive tract, it simply passes through the body without providing benefits—regardless of how much active ingredient the label claims.

The absorption challenge extends beyond simple solubility. B vitamins must be released at the right location in the digestive system and at the right rate. Release them too early in the stomach, and acidic conditions may degrade them. Release them too late, and they may pass the primary absorption sites in the small intestine. This is why sophisticated manufacturers invest in formulation technologies that control where and how vitamins are released.

Bioavailability also depends on the specific form of each B vitamin used in the formulation. For example, methylcobalamin and cyanocobalamin are both forms of vitamin B12, but they have different absorption profiles and bioavailability characteristics. The same applies to other B vitamins—folic acid versus methylfolate, pyridoxine versus pyridoxal-5-phosphate. Choosing the right forms requires deep understanding of both biochemistry and manufacturing capabilities.

When bioavailability is poor, consumers take their supplements faithfully yet see minimal results. Blood tests may still show deficiencies despite regular supplementation. This isn’t just disappointing—it erodes trust in the entire supplement industry and highlights why technical expertise in formulation matters just as much as ingredient purity.

The Viscosity Challenge in Liquid Formulations

Liquid B complex supplements have grown increasingly popular due to their ease of consumption and potentially faster absorption. However, liquid formulations introduce unique challenges that solid dosage forms don’t face.

Viscosity management emerges as a critical factor in liquid supplement quality. B complex vitamins must remain uniformly suspended throughout the liquid medium. If viscosity is too low, heavier ingredients settle to the bottom, creating sedimentation that leads to inconsistent dosing. The first half of the bottle delivers insufficient nutrients, while the last few doses contain excessive concentrations—neither scenario is acceptable.

On the other hand, if viscosity is too high, the product becomes difficult for consumers to pour and measure accurately. It may also create manufacturing challenges, making it harder to fill bottles precisely and increasing the likelihood of air bubbles or incomplete filling. High viscosity can also interfere with the dissolution and absorption of the vitamins themselves.

The ingredients used to manage viscosity must be carefully selected. They need to be compatible with all the B vitamins in the formulation, maintain stability across the product’s shelf life, and not interfere with bioavailability. Some thickening agents can actually bind to vitamins, reducing their absorption. Others may create an environment that accelerates degradation.

Temperature changes during storage and shipping add another dimension to the viscosity challenge. A formulation that maintains perfect consistency at room temperature might become too thick in cold conditions or too thin in summer heat. This is particularly relevant for products that ship across diverse climates or sit in warehouses with variable temperature control.

These viscosity considerations aren’t just technical details—they directly impact consumer experience and product efficacy. A liquid supplement that requires constant shaking, delivers inconsistent doses, or develops an off-putting texture will quickly lose consumer trust, regardless of how pure the raw ingredients were initially.

Innovation in Formulation Technology

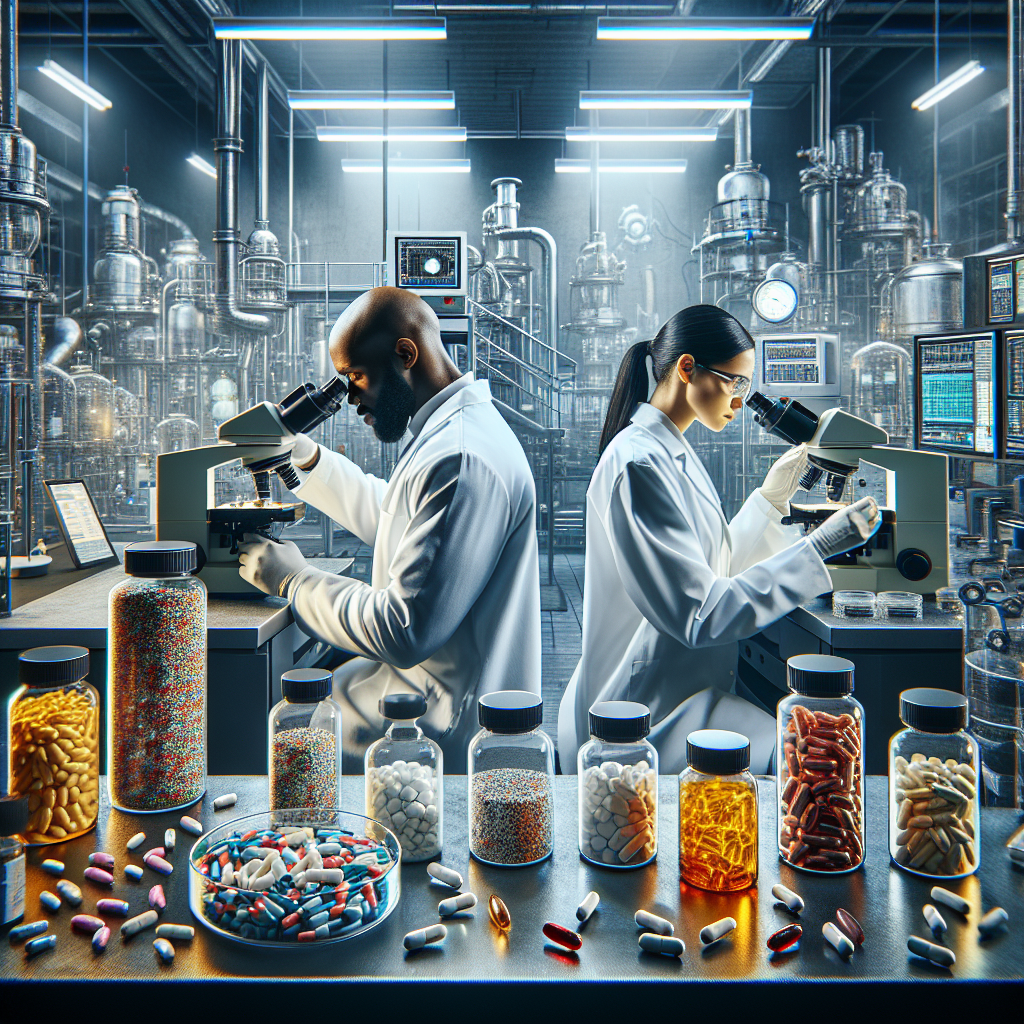

Forward-thinking manufacturers are addressing these challenges through sophisticated formulation techniques that go far beyond simply mixing ingredients together.

Controlled release technology represents one of the most promising approaches. By designing formulations that release B vitamins gradually over several hours, manufacturers can optimize absorption while reducing the risk of degradation in harsh stomach acid. Sustained release systems improve both efficacy and bioavailability by delivering nutrients to the intestinal absorption sites in a controlled manner. Advanced controlled release technologies now enable precise timing of nutrient delivery throughout the digestive system. This approach also provides more consistent blood levels of vitamins throughout the day, mimicking how nutrients would be absorbed from food sources.

Microencapsulation has emerged as another powerful tool. By surrounding individual vitamin molecules with protective coatings, manufacturers can shield sensitive nutrients from degradation factors like light, oxygen, and pH changes. These microscopic capsules can be engineered to release their contents at specific locations in the digestive tract or in response to particular pH levels. Research has confirmed that encapsulation techniques effectively address the stability challenges that have long plagued vitamin B2 and other sensitive nutrients.

Liposomal technology takes a different approach by encasing vitamins in lipid spheres that mimic cell membranes. This method can dramatically enhance bioavailability, particularly for vitamins that have historically shown poor absorption rates. Liposomal formulations also protect vitamins during storage and transit through the digestive system.

Patient-centric design—or consumer-centric design in the supplement industry—focuses on creating products that people actually want to take. This includes developing alternative formats like gummies, sublingual tablets, or dissolvable strips that provide more pleasant consumption experiences while maintaining stability and bioavailability. Advanced manufacturing techniques now allow for precise dosing and improved stability even in these convenient formats.

Nanotechnology applications represent the cutting edge of formulation science. Nanocarriers, including polymeric, lipid-based, and metal-based systems, can enhance vitamin stability and bioavailability in ways that weren’t possible just a few years ago. While still emerging, these technologies show remarkable promise for addressing the most stubborn challenges in B complex formulation.

Quality Control: The Backbone of Potency

Innovative formulation techniques only work when paired with rigorous quality control measures. This is where theoretical formulation science meets practical manufacturing reality.

Stability testing forms the foundation of quality assurance. Comprehensive testing protocols evaluate how formulations behave under various conditions—elevated temperatures, humidity exposure, light exposure, and extended time periods. Accelerated stability studies simulate months or years of shelf life in condensed timeframes, allowing manufacturers to identify potential degradation issues before products reach consumers. Recent research emphasizes that comprehensive stability testing protocols remain essential for ensuring supplements retain their potency, efficacy, and physical integrity under various storage conditions.

Real-time stability programs track products throughout their actual shelf life, providing data on how formulations perform under real-world conditions. This ongoing monitoring helps manufacturers continuously refine their formulations and storage recommendations. It also provides the documentation needed to support expiration dates and potency guarantees.

In-process testing during manufacturing catches potential problems before they become finished products. This includes monitoring temperatures during granulation, checking dissolution rates of tablets, verifying uniform distribution in liquid formulations, and testing viscosity at multiple points during production. Each manufacturing batch should undergo comprehensive testing before release.

Third-party verification adds another layer of confidence. Independent laboratory testing confirms that what’s on the label matches what’s in the bottle, both at the time of manufacture and throughout the product’s shelf life. This transparency benefits everyone—manufacturers gain credibility, and consumers receive products they can trust.

Raw material testing represents the first line of defense in quality control. Before any ingredient enters the manufacturing process, it should undergo thorough analysis to verify identity, purity, potency, and absence of contaminants. This upstream quality control approach prevents problems from ever entering the supply chain. This upstream quality control prevents problems from ever entering the supply chain.

Regulatory Compliance and Industry Trust

The supplement industry operates in a complex regulatory environment where quality standards and transparency requirements continue to evolve. Meeting these requirements isn’t just about avoiding penalties—it’s about building the consumer trust that sustains long-term business success.

FDA regulations require that dietary supplements be manufactured according to Current Good Manufacturing Practices (cGMP), which mandate specific quality control measures, documentation practices, and facility standards. These regulations exist because vitamin supplements can lose potency over time, and consumers deserve products that deliver what labels promise from manufacture through expiration.

USP standards provide additional benchmarks for ingredient quality, testing methodologies, and product specifications. Exceeding these standards—not just meeting them—demonstrates a commitment to excellence that differentiates premium manufacturers from those taking shortcuts.

Complete documentation throughout the supply chain enables true transparency. This includes certificates of analysis for raw materials, batch records from manufacturing, stability testing data, and full traceability from source to finished product. When quality issues arise, comprehensive documentation allows for rapid identification of root causes and swift corrective action.

Supply chain visibility has become increasingly important as consumers demand to know where their supplements come from and how they’re made. This transparency extends from raw material sourcing through manufacturing processes to storage and distribution. Companies that provide this visibility earn consumer trust that translates into brand loyalty.

Building Trust Through Excellence

The challenges in B complex manufacturing aren’t insurmountable—they simply require expertise, investment in quality systems, and partnership with suppliers who share a commitment to excellence. Manufacturers who understand these challenges and address them proactively create products that truly serve consumers.

This is where NutraAeon’s philosophy of quality, transparency, and empowerment comes into play. As a global nutritional ingredients partner, NutraAeon recognizes that premium B complex supplements begin with exceptional raw materials. Industry-leading testing protocols ensure that every ingredient meets rigorous quality standards before it reaches manufacturing facilities. Complete documentation and certificates of analysis provide the transparency that manufacturers need to make informed decisions and support their own quality claims.

But quality alone isn’t enough. Empowerment through technical expertise helps manufacturers navigate the complex formulation challenges inherent in B complex products. This includes guidance on selecting the right forms of B vitamins for specific applications, advice on stability-enhancing techniques, and insights into regulatory requirements across different markets.

For forward-thinking supplement manufacturers seeking to create products that stand out in a crowded marketplace, the path forward is clear. It requires partnering with ingredient suppliers who understand that premium nutrition starts with premium ingredients, backed by rigorous testing, complete transparency, and the technical expertise to support successful formulation.

The B complex vitamins that consumers take each morning should deliver the potency and efficacy they deserve. Achieving this requires manufacturers who refuse to accept compromise, suppliers who provide exceptional ingredients and support, and an industry-wide commitment to transparency and quality. When these elements align, everyone benefits—manufacturers build trusted brands, consumers receive products that work, and the supplement industry as a whole moves forward.

Your B complex vitamins don’t have to lose potency before reaching consumers. With the right approach, they can maintain their full nutritional value from manufacturing through consumption, delivering the health benefits that make these essential nutrients so valuable.