Every supplement manufacturer knows the sinking feeling when a supplier shipment arrives and something’s wrong. Maybe the amino acid purity is off by 2%. Perhaps the certificates of analysis don’t match the batch. Or worse, you discover quality issues only after your product reaches customers.

These aren’t just operational hiccups. They’re symptoms of a fundamental problem: making supplier decisions without a standardized evaluation framework. The good news? A simple Excel vendor evaluation template can prevent most of these disasters before they happen.

Vendor evaluation isn’t just paperwork. It’s the strategic foundation of your entire sourcing operation. For supplement manufacturers working with nutritional ingredients, where quality directly impacts consumer health and brand reputation, systematic vendor assessment becomes even more critical. A well-designed Excel scorecard transforms subjective supplier opinions into objective, comparable data that protects your business from costly mistakes.

The beauty of Excel templates lies in their simplicity. You don’t need expensive procurement software or complex IT infrastructure. A free, customizable spreadsheet standardizes how you assess every potential supplier, eliminates personal bias from the decision-making process, and creates a documented record of why you chose one vendor over another. This matters when regulatory agencies ask questions, when finance needs to justify purchasing decisions, or when you’re scaling operations and need consistent evaluation criteria across multiple buyers.

Building Blocks: What Makes a Vendor Evaluation Template Actually Work

An effective vendor evaluation template contains three essential components that work together to create a complete supplier profile. Each component serves a specific purpose in transforming raw information into actionable procurement intelligence.

The first component is detailed vendor information. This section captures the fundamental facts about each potential supplier: company name, contact details, years in business, certifications held, production capacity, and geographic location. For nutritional ingredient suppliers, this includes critical specifics like GMP certification status, whether they hold FDA registrations, their testing laboratory accreditations, and documentation of their quality management systems. This isn’t just administrative data. When you’re sourcing L-Theanine or Vitamin C Palmitate, knowing that a supplier operates from a facility with NSF certification versus one without tells you something essential about their quality infrastructure.

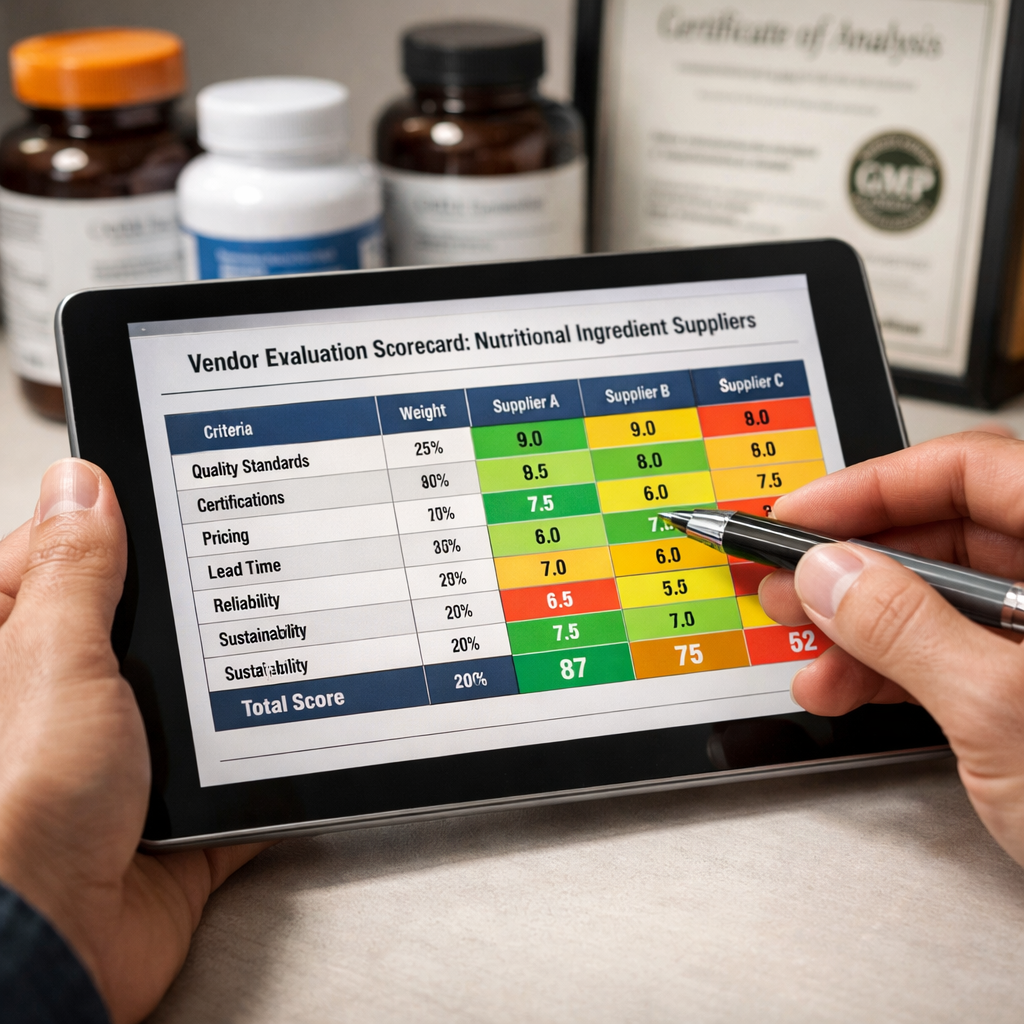

The second component is the evaluation matrix itself. This is where you define the specific criteria that matter for your business and create a structured framework for assessment. Quality standards, pricing competitiveness, delivery reliability, technical support capabilities, regulatory compliance, financial stability, and innovation capacity all become measurable dimensions. The matrix translates abstract concepts like “good quality” into concrete, scorable attributes. Does the supplier provide third-party testing for every batch? Can they deliver within your required lead times? Do they offer technical formulation support? Each question gets a defined scoring scale that eliminates guesswork.

The third component is the scoring calculation system. This is the mathematical engine that converts your individual assessments into an overall vendor score. Simple weighted averages work for most applications: assign importance weights to each criterion based on strategic priorities, multiply each criterion score by its weight, then sum everything into a final number. The calculation system should also include threshold logic that automatically flags suppliers who score below acceptable minimums or highlight those exceeding expectations. When you’re comparing five potential suppliers for premium Magnesium Oxide, these calculated scores make the best choice immediately obvious.

Why Excel Templates Accelerate Better Procurement Decisions

Excel templates deliver three concrete benefits that directly impact your procurement outcomes and risk exposure.

First, they dramatically speed up decision-making. Without a template, vendor evaluation becomes a time-consuming process of gathering scattered information, scheduling multiple meetings, and trying to remember which supplier said what during phone calls three weeks ago. A standardized template creates a consistent information collection framework. Every supplier receives the same questions and gets evaluated against identical criteria. You can complete assessments in parallel rather than sequentially. What might take six weeks of back-and-forth communication compresses into ten days of focused evaluation. For manufacturers launching new formulations or responding to market opportunities, this speed advantage translates directly into competitive edge.

Second, templates substantially improve risk management. They force you to ask the right questions before committing to a supplier relationship. Has the vendor experienced any recalls in the past five years? What’s their average on-time delivery rate? Do they maintain insurance coverage adequate for your purchase volumes? These critical questions form the foundation of effective supplier evaluation questionnaires. These questions often get overlooked in informal evaluation processes, only to become expensive problems later. A comprehensive template ensures nothing critical slips through the cracks. When you’re sourcing amino acids for sports nutrition products, knowing a supplier’s contamination prevention protocols upfront prevents devastating product recalls down the road.

Third, the free availability and customization potential of Excel templates remove barriers to implementation. You don’t need procurement software licenses, IT department involvement, or training budgets. Download a template, modify it to reflect your specific requirements, and start using it immediately. Need to add evaluation criteria specific to nutritional ingredients? Insert a new column. Want to adjust weights based on lessons learned? Change the formula. This flexibility ensures your evaluation framework evolves with your business rather than locking you into rigid systems designed for different industries.

Structuring Your Scorecard: The Framework That Makes Comparisons Meaningful

The power of a vendor scorecard comes from how you structure it. Three design decisions determine whether your template generates useful insights or just creates more paperwork.

Start with criterion selection. Identify five to ten key dimensions that genuinely predict supplier success for your specific needs. Common core criteria include quality management systems, pricing competitiveness, delivery performance, technical expertise, and financial stability. For supplement manufacturers, add industry-specific dimensions: ingredient purity guarantees, testing protocol rigor, regulatory documentation completeness, supply chain transparency, and batch-to-batch consistency. Each criterion should be measurable, observable, and relevant to actual supplier performance. Avoid vague dimensions like “overall impression” that inject subjectivity back into the process.

Next comes weight assignment. Not all criteria matter equally. A supplier scoring 100% on price but only 60% on quality represents a disaster for premium supplement brands. Assign weights based on strategic importance. If your brand positioning emphasizes quality above everything else, quality criteria might carry 40% of the total score while price carries only 15%. If you’re competing in price-sensitive markets, reverse those weights. The key insight is that weights should reflect your actual priorities, not what sounds good in theory. Learn more about strategic ingredient sourcing priorities that drive business success. For NutraAeon’s quality-first philosophy, evaluation templates would heavily weight factors like testing protocols, documentation completeness, and supply chain transparency because these directly enable the quality, transparency, and empowerment that define the company’s approach to ingredient sourcing.

Finally, establish clear thresholds for approval. A scoring scale from 1-5 or 1-10 creates granularity, but you need defined cutoffs. Perhaps suppliers scoring below 7.0 overall are automatically disqualified. Maybe any vendor scoring below 8.0 on quality requires executive approval to proceed. Specific criteria might have absolute minimums: if a supplier doesn’t hold current GMP certification, they can’t even enter evaluation regardless of their scores elsewhere. These thresholds prevent the temptation to rationalize poor performers and maintain procurement standards across your organization.

Consider practical examples. Quality criteria might include subcategories: certificate of analysis completeness (weight: 25%), third-party testing frequency (weight: 25%), contamination control procedures (weight: 30%), and audit history (weight: 20%). For comprehensive quality frameworks, explore our quality control resources. Price evaluation could break down into unit cost competitiveness, payment terms flexibility, and volume discount structure. Sustainability increasingly matters to health-conscious consumers, so environmental practices, ethical sourcing verification, and carbon footprint transparency become scoreable dimensions that differentiate suppliers in commoditized ingredient categories.

The NutraAeon Approach: How Rigorous Assessment Ensures Ingredient Excellence

The connection between systematic vendor evaluation and ingredient quality isn’t abstract. It’s the operational mechanism that makes brand promises real.

Consider NutraAeon’s core philosophy of quality, transparency, and empowerment. These values don’t manifest through good intentions alone. They require concrete procurement practices that systematically identify and select suppliers capable of delivering premium ingredients. A comprehensive vendor evaluation template operationalizes these values by translating philosophical commitments into measurable assessment criteria.

Quality doesn’t happen by accident. It results from deliberate supplier selection that prioritizes testing protocols, documentation standards, and production controls over price considerations. When evaluating potential suppliers for L-Theanine or Vitamin E tocopherols, NutraAeon-aligned assessment criteria would heavily weight factors like whether suppliers conduct batch-level testing, maintain validated analytical methods, and provide complete chain-of-custody documentation. These aren’t bureaucratic requirements. They’re the specific practices that separate ingredients meeting USP specifications from those falling short in ways that compromise formulation efficacy or consumer safety.

Transparency becomes real through vendor evaluation criteria that assess supply chain visibility. Does a supplier willingly share production facility details? Can they trace ingredients back to their original sources? Do they proactively communicate potential issues before they impact delivery? Comprehensive supplier qualification checklists address these transparency indicators systematically. These transparency indicators predict whether a supplier relationship will involve constant communication gaps and surprises or smooth, collaborative operations. For supplement manufacturers requiring complete documentation for regulatory submissions, supplier transparency directly determines whether formulation development proceeds smoothly or encounters constant documentation delays.

Empowerment for manufacturers comes from selecting suppliers who offer more than just commodity ingredients. Evaluation criteria should assess technical support capabilities, formulation expertise availability, regulatory guidance provision, and market intelligence sharing. A supplier scoring 95% on price but offering zero technical support might work for basic ingredients in established formulations. For innovative supplements targeting competitive health and wellness markets, manufacturers need suppliers who function as strategic partners, contributing expertise beyond just fulfilling purchase orders. Evaluation templates that explicitly score these value-added dimensions help identify suppliers who truly empower better product development.

Implementation requires commitment beyond just downloading a template. Start by customizing the framework to reflect your actual strategic priorities. If sustainability matters to your brand, include scored environmental criteria. If you’re entering specialized nutrition markets, add regulatory expertise dimensions. Then establish consistent processes: every new supplier enters evaluation before any purchase order, existing suppliers undergo annual re-evaluation, and purchasing decisions below threshold scores require documented exception justifications.

Train your team on using the template consistently. If three different buyers interpret quality criteria differently, you lose the standardization benefits that make scorecards valuable. Create clear definitions for each criterion and provide scoring guidelines that minimize subjective interpretation. Consider including actual examples: “A score of 5 on delivery reliability means on-time delivery above 98% over the past 12 months with zero stockouts.”

Taking Action: From Template to Better Supplier Decisions

The gap between knowing you need better vendor evaluation and actually implementing it comes down to taking specific first steps. Here’s how to move from reading about templates to using them.

Download a free vendor evaluation template today. Multiple resources offer Excel-based templates designed for manufacturing and procurement. Look for templates that include the three core components: vendor information capture, evaluation matrix with weighted scoring, and automatic calculation systems. Most require minimal modification to work for nutritional ingredient sourcing. The investment is fifteen minutes of download and review time.

Customize the template for your unique requirements. Supplement manufacturers face specific considerations that generic procurement templates might miss. Add evaluation criteria for ingredient purity guarantees, testing frequency, allergen control procedures, and regulatory documentation quality aligned with FDA guidelines. Adjust weights to reflect whether you’re positioning as a premium quality brand or competing on value. Include any must-have certifications specific to your target markets. This customization ensures your evaluation reflects real priorities rather than generic best practices.

Pilot the template with your next supplier selection or with re-evaluating current suppliers. Don’t wait for perfect circumstances or complete process documentation. Start small and learn by doing. Choose one ingredient category and three potential suppliers. Work through the evaluation systematically, noting what works smoothly and what needs refinement. This practical experience reveals template improvements that theoretical planning misses. You’ll discover which criteria are easy to score versus which require additional supplier information requests. You’ll identify whether your weighting truly reflects strategic priorities or needs adjustment.

Share results with your team and iterate. Vendor evaluation shouldn’t be one person’s spreadsheet hidden on a desktop. Make it a shared organizational asset. Review evaluation results collaboratively to ensure scoring consistency across buyers. Discuss what thresholds make sense given real supplier options in the market. Adjust weights based on lessons learned from supplier performance. This collaborative approach builds organizational consensus around procurement standards and improves decision quality over time.

Finally, view vendor evaluation as the beginning of strategic supplier partnerships, not just a selection gate. The best suppliers don’t just meet specifications. They collaborate on formulation optimization, proactively communicate market changes, invest in quality improvements, and function as extensions of your product development team. Once your template identifies high-scoring suppliers, deepen those relationships through regular performance reviews, innovation partnerships, and long-term contracts that reward excellence. Discover strategies for building resilient global sourcing networks. This transforms tactical purchasing into strategic sourcing that generates competitive advantage.

The supplement industry grows more competitive every year. Consumers demand higher quality, greater transparency, and more innovative formulations. Regulatory scrutiny intensifies. Supply chains grow more complex. In this environment, informal supplier evaluation based on personal relationships and historical precedent creates unacceptable risk.

A simple Excel vendor evaluation template represents a fundamental upgrade to procurement practice. It costs nothing, requires minimal time to implement, and generates immediate value by standardizing how you assess suppliers. More importantly, it prevents the expensive disasters that happen when inadequate suppliers enter your supply chain and quality problems emerge only after significant investment.

The manufacturers who thrive aren’t those with the biggest budgets or longest histories. They’re the ones who make systematically better decisions about every aspect of their operations, including which suppliers earn their business. A vendor evaluation scorecard is one decision improvement tool that every supplement manufacturer can implement starting today.