In the competitive world of dietary supplements, the difference between a product that delivers on its promises and one that falls short often comes down to a single critical factor: vitamin stability testing. Before any supplement reaches store shelves or a consumer’s medicine cabinet, it must undergo rigorous evaluation to ensure that what’s listed on the label accurately reflects what’s inside the bottle—not just on day one, but throughout the product’s entire shelf life.

Vitamin stability testing represents the scientific backbone of quality assurance in nutritional manufacturing. This comprehensive evaluation process determines how vitamins and other nutritional ingredients behave under real-world conditions, from the moment they’re formulated until the expiration date printed on the package. For manufacturers, understanding and implementing robust stability testing protocols isn’t just about regulatory compliance—it’s about honoring the trust that consumers place in their products and delivering genuine health benefits.

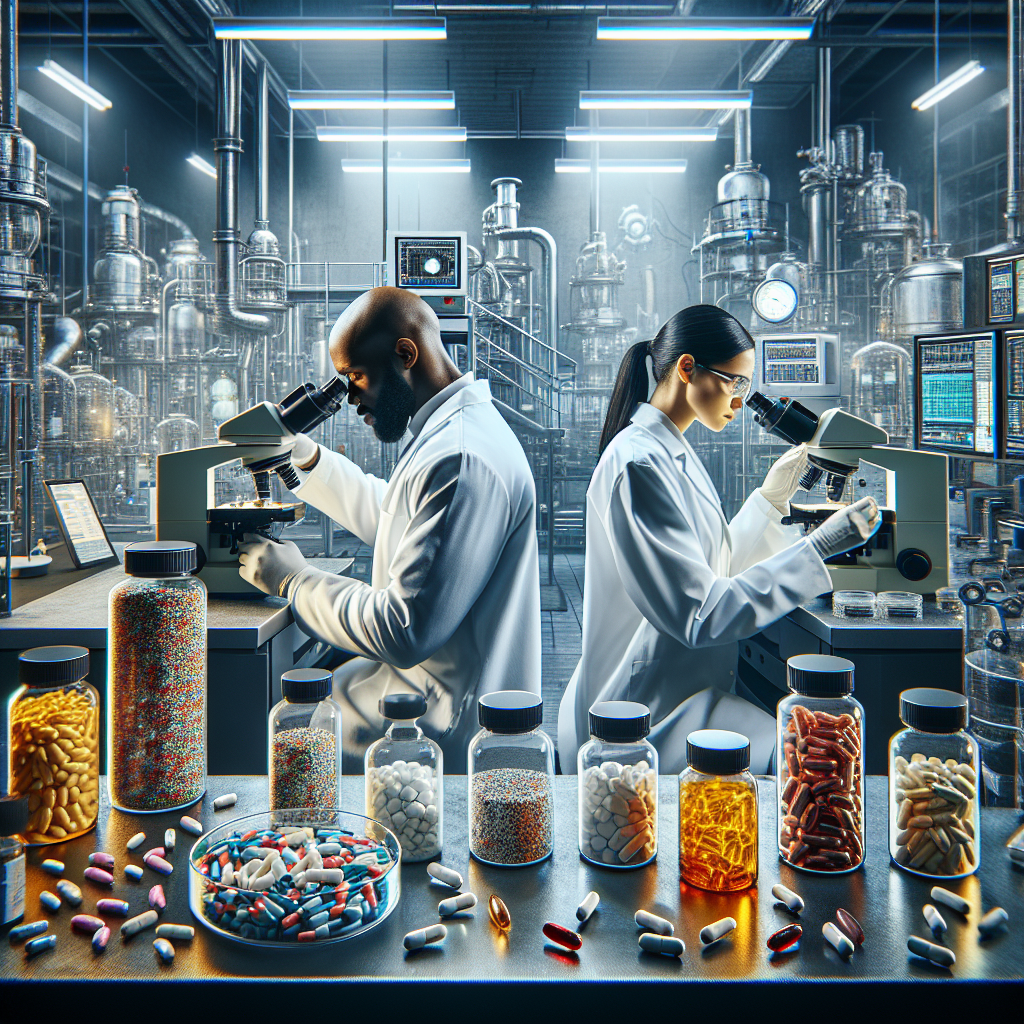

At NutraAeon, we recognize that stability testing embodies our core principles of quality, transparency, and empowerment. When manufacturers partner with us for premium nutritional ingredients, they’re not just receiving raw materials; they’re gaining access to ingredients backed by comprehensive stability data and technical expertise. This commitment ensures that formulations maintain their potency and deliver the health outcomes that consumers expect and deserve.

Why Vitamin Stability Testing Matters More Than You Think

The importance of stability testing extends far beyond checking a regulatory box. When vitamins degrade, they don’t simply become less effective—they can fundamentally compromise the integrity of your entire product. Research shows that nutrient degradation is driven by multiple factors, with liquid formats, temperature fluctuations, and pH levels playing particularly critical roles in how quickly vitamins lose their potency.

Consider vitamin A, which demonstrates remarkable stability in acidic liquid products but shows marked degradation in non-acidified formulations, especially when stored at elevated temperatures between 25-30°C. This single example illustrates why manufacturers cannot take a one-size-fits-all approach to stability. Each formulation requires careful consideration of how ingredients interact with their environment and with each other.

Stability testing ensures that products maintain three essential qualities throughout their shelf life: potency, safety, and overall quality. When a consumer purchases a vitamin C supplement promising 1000mg per serving, they trust that the product will deliver that amount whether they open the bottle immediately or six months before the expiration date. Without proper stability testing, manufacturers risk delivering products that promise one thing but deliver another—a breach of trust that can damage brand reputation permanently.

The data gathered from stability studies also informs crucial storage and handling guidelines. Should products be stored in a cool, dry place? Do they require refrigeration? Can they tolerate temperature fluctuations during shipping? These practical recommendations stem directly from empirical stability data and help ensure product quality from manufacturing facility to consumer home.

For NutraAeon’s partners, this commitment to stability testing means that every amino acid, vitamin, and mineral in our portfolio comes with complete documentation demonstrating how it performs under various conditions. When formulating with our L-Theanine for stress relief or our multiple forms of vitamin C, manufacturers gain access to stability profiles that support confident product development and accurate shelf-life determinations.

The Key Elements of Robust Stability Testing Protocols

Effective vitamin stability testing requires careful attention to multiple parameters that mirror real-world storage and usage conditions. Understanding these elements helps manufacturers design studies that generate meaningful, actionable data for their specific products and target markets.

Temperature stands as perhaps the most critical variable in stability testing. Packaged pharmaceutical products are placed inside stability chambers maintained at specific temperatures for set periods, with common testing conditions including 25°C/60% relative humidity for room temperature storage, 30°C/65% RH for warmer climates, and 40°C/75% RH for accelerated testing. These controlled environments simulate how products behave across different geographic regions and seasons, providing manufacturers with comprehensive stability profiles.

Humidity control works hand-in-hand with temperature regulation. Moisture can trigger chemical reactions, promote microbial growth, and compromise packaging integrity. Testing protocols carefully monitor relative humidity levels throughout study periods, ensuring that products demonstrate stability under both typical and challenging moisture conditions. This becomes especially important for hygroscopic ingredients that readily absorb moisture from their environment.

Light exposure represents another crucial testing parameter. Many vitamins, particularly riboflavin, vitamin A, and certain forms of vitamin D, demonstrate photosensitivity and degrade when exposed to ultraviolet or visible light. Stability chambers can simulate various light conditions, from complete darkness to continuous exposure, helping manufacturers determine appropriate packaging requirements—whether products need amber glass, opaque containers, or UV-protective coatings.

Container type and packaging materials significantly influence stability outcomes. The same formulation may show vastly different stability profiles when packaged in glass versus plastic, or when protected by different closure systems. Testing protocols evaluate how packaging materials interact with product ingredients, whether they provide adequate oxygen barriers, and if they maintain integrity under stress conditions.

At NutraAeon, our industry-leading testing protocols evaluate all these parameters and more. Our technical team understands that vitamin stability testing isn’t about running generic tests—it’s about designing studies that reflect how products will actually be used, stored, and transported in real-world scenarios. This comprehensive approach ensures that our ingredient partners receive actionable data that supports successful product launches and sustained market presence.

The Science Behind Designing Effective Stability Studies

Well-designed stability studies follow scientific principles that assess both physical and chemical changes in products over time. These studies provide the empirical foundation for shelf-life claims, storage recommendations, and quality specifications that manufacturers communicate to consumers and regulatory agencies.

The primary aim of stability studies is determining expiration dates while ensuring products maintain standardized efficacy throughout their claimed shelf life. This requires periodic analysis of product composition, with testing intervals typically occurring at 0, 3, 6, 9, 12, 18, and 24 months, and sometimes extending further for products claiming longer shelf lives.

Chemical stability testing evaluates potency retention—how well vitamins maintain their labeled strength over time. For vitamin C products, this means measuring ascorbic acid content at regular intervals and tracking degradation rates under various conditions. For amino acid formulations like NutraAeon’s L-Tryptophan for sleep quality or L-Serine for cognitive support, testing confirms that active compounds remain at specified concentrations throughout the shelf life.

Physical stability assessment monitors characteristics like appearance, color, odor, texture, and dissolution properties. A tablet that becomes discolored, develops an off-odor, or fails to dissolve properly has experienced physical instability, even if chemical potency remains intact. These changes can signal deeper quality issues and significantly impact consumer acceptance.

Comprehensive testing protocols also screen for microbial contamination, ensuring products remain free from harmful bacteria, yeast, and mold throughout their shelf life. Testing for heavy metals and allergens provides additional safety assurance, confirming that products meet stringent quality standards from manufacturing through expiration.

For manufacturers working with NutraAeon’s comprehensive ingredient portfolio—from our high-purity amino acid series to our complete B-complex vitamin family—access to technical expertise and regulatory guidance transforms stability testing from a challenging obligation into a competitive advantage. Our team helps partners navigate the complexities of study design, ensuring that testing protocols generate data that supports both regulatory submissions and marketing claims.

Determining Shelf Life Through Data-Driven Analysis

The process of establishing accurate shelf life claims requires careful analysis of empirical data collected throughout stability studies. Manufacturers conduct stability tests by storing supplements in controlled environments and periodically analyzing their composition, building a comprehensive picture of how products change over time.

Shelf life determination balances scientific rigor with practical considerations. The goal is identifying the time period during which a product maintains at least 90-95% of its labeled potency while meeting all quality specifications for safety, purity, and physical characteristics. This threshold ensures consumers receive effective products while accounting for normal degradation patterns.

Data analysis involves plotting nutrient concentrations against time, identifying degradation curves, and applying statistical methods to project when products will fall below acceptable potency thresholds. For stable ingredients like NutraAeon’s premium mineral compounds, including our food-grade magnesium oxide, degradation may be minimal, supporting longer shelf lives. For more sensitive nutrients, especially in liquid formulations, shelf lives may be considerably shorter.

Adherence to regulatory guidelines remains paramount throughout this process. The FDA’s current Good Manufacturing Practices (cGMP) for dietary supplements require manufacturers to establish product specifications, conduct appropriate testing, and maintain documentation supporting shelf life claims. Our results show that transparency in this documentation—providing complete certificates of analysis and full supply chain visibility—builds trust with regulatory agencies, retail partners, and end consumers.

Ongoing stability studies provide additional assurance beyond initial shelf life determination. While these studies don’t need to align perfectly with primary stability protocols, testing should continue through the end of the retest period or expiration date. This ongoing monitoring confirms that products perform as expected in real-world conditions and allows manufacturers to identify potential issues before they impact consumers.

NutraAeon’s commitment to transparency and documentation means our manufacturing partners receive comprehensive stability data for every ingredient they source through our network. Whether formulating with our vitamin E tocopherols, vitamin C palmitate, or glycine for sports nutrition applications, manufacturers gain access to detailed stability profiles that support confident shelf life claims and regulatory compliance.

Building Consumer Trust Through Quality Assurance

In today’s health-conscious marketplace, consumers increasingly scrutinize supplement quality and demand products that deliver on their promises. Robust vitamin stability testing protocols serve as the foundation for meeting these expectations and building lasting consumer trust.

The role of stability testing in supplement quality cannot be overstated. When manufacturers invest in comprehensive testing, they’re making a statement about their commitment to excellence and their respect for consumer health. Products backed by thorough stability data don’t just meet minimum regulatory requirements—they exceed consumer expectations by delivering consistent potency and quality from first dose to last.

This commitment resonates particularly strongly with forward-thinking supplement manufacturers who recognize that cutting corners on stability testing ultimately costs more than it saves. A product recall, negative reviews highlighting ineffective products, or regulatory warnings can devastate a brand’s reputation far more completely than the investment required for proper stability testing.

For enterprise businesses requiring strategic ingredient partnerships and small businesses with R&D capabilities, partnering with suppliers who prioritize stability testing creates competitive advantages. NutraAeon’s comprehensive supply network bridges global ingredient excellence with innovative manufacturing, ensuring that every component of your formulation—from amino acids supporting cognitive function to vitamins promoting immune health—meets the demanding needs of today’s health-conscious consumers.

Nutritional product developers and health-conscious product manufacturers who work with premium ingredients backed by rigorous stability data can market their products with confidence. They can point to specific testing protocols, share stability data with retail partners, and answer consumer questions with detailed, scientifically-grounded information. This transparency transforms product quality from an abstract concept into a tangible competitive differentiator.

The Path Forward: Implementing Excellence in Stability Testing

As the dietary supplement industry continues evolving, the importance of vitamin stability testing will only increase. Consumers expect more from their supplements—better quality, greater transparency, and products that genuinely support their health goals. Regulatory agencies continue refining their expectations, requiring more comprehensive documentation and stricter adherence to quality standards.

For manufacturers navigating this landscape, the path forward requires commitment to robust stability testing protocols that ensure products deliver safe, effective, and high-quality outcomes throughout their shelf lives. This means investing in proper testing facilities, whether in-house or through qualified contract laboratories, and designing study protocols that reflect real-world conditions and potential stress factors.

It means selecting ingredient partners who share this commitment to quality and who provide comprehensive stability data for every raw material. When sourcing amino acids, vitamins, or minerals, manufacturers should demand complete documentation, certificates of analysis, and stability profiles that support confident formulation decisions.

Most importantly, it means recognizing that stability testing isn’t a burden to be minimized—it’s an investment in product excellence that pays dividends through enhanced consumer trust, reduced quality issues, and stronger market positioning. The manufacturers who embrace this perspective, who view stability testing as integral to their quality commitment rather than a regulatory checkbox, will be the ones who thrive in an increasingly competitive marketplace.

At NutraAeon, we believe that delivering excellence through quality, transparency, and empowerment means providing manufacturing partners with more than just ingredients—we provide the technical expertise, comprehensive documentation, and regulatory guidance that transform good products into exceptional ones. Our vision of being the premier global sourcing partner for nutritional ingredients centers on helping manufacturers create products that stand out through scientific expertise, market insights, and unwavering commitment to excellence.

As you develop your next formulation or evaluate your current product line, remember that vitamin stability testing represents far more than a technical requirement. It embodies your commitment to consumer health, your dedication to product quality, and your vision for building a brand that consumers trust. With proper testing protocols, quality ingredients, and expert guidance, you can create products that not only meet today’s demanding standards but set new benchmarks for excellence in the dietary supplement industry.