In a world of specialized materials, few substances demonstrate the remarkable versatility of magnesium oxide. This unassuming white powder stands as a silent titan across diverse industries, from the scorching environments of steel furnaces to the delicate balance of nutritional supplements. As industries evolve and innovation accelerates, understanding what magnesium oxide is and its multifaceted applications becomes increasingly valuable for businesses seeking competitive advantages in their respective fields.

Magnesium oxide serves as an industrial powerhouse in manufacturing processes while simultaneously providing essential health benefits in nutritional applications. Its unique combination of thermal stability, chemical resistance, and alkaline properties has made it indispensable across sectors ranging from construction to environmental management. For forward-thinking manufacturers and product developers, recognizing the full potential of this mighty mineral can unlock new opportunities for product innovation and efficiency.

Understanding Magnesium Oxide: Composition and Properties

At its core, what is magnesium oxide? Simply put, it’s an inorganic compound with the chemical formula MgO, consisting of magnesium ions (Mg²⁺) and oxide ions (O²⁻) bound together in a crystalline structure. This basic salt of magnesium occurs naturally in the mineral periclase but is typically produced commercially by calcining magnesium carbonate or magnesium hydroxide at high temperatures.

The resulting white powder possesses remarkable properties that explain its industrial significance:

- Exceptional thermal stability with a melting point of 2,852°C and boiling point of 3,600°C

- High electrical resistivity, making it an excellent insulator

- Strong resistance to chemical attack, particularly from alkaline substances

- Impressive thermal conductivity despite its insulating properties

- Ability to withstand significant heat without degrading

These characteristics aren’t merely academic distinctions—they translate directly into practical applications across numerous industries. The compound exists in two primary forms: light magnesium oxide (with a lower density and higher reactivity) and heavy magnesium oxide (more dense and less reactive), each suited to different applications based on their physical properties.

Refractory Applications: Withstanding Extreme Heat

Perhaps most notably, magnesium oxide has established itself as an indispensable component in refractory materials—substances designed to withstand extraordinarily high temperatures in industrial processes. These materials line furnaces, kilns, and reactors used in metal production and other manufacturing operations where extreme heat is necessary.

What is magnesium oxide’s value in this context? Its exceptional heat resistance makes it ideal for creating refractory bricks, crucibles, and linings that protect equipment while ensuring efficient heat transfer. In steel production facilities, where temperatures regularly exceed 1,600°C, MgO-based refractories resist corrosion from molten metal and slag while maintaining structural integrity. For businesses in metallurgical industries, this translates to longer equipment lifespans, reduced maintenance costs, and more consistent production quality.

Advanced ceramics manufacturers similarly rely on magnesium oxide as a key ingredient in specialized ceramic formulations. These high-performance ceramics find applications in electronics, aerospace, and other sectors where materials must perform reliably under extreme conditions.

Construction Applications: Building Stronger Foundations

The construction industry has increasingly embraced magnesium oxide as a valuable material for creating durable, sustainable building components. MgO boards, made from magnesium oxide powder combined with various fillers and reinforcing materials, offer compelling advantages over traditional construction boards as highlighted in The Ultimate Guide to Magnesium Oxide Boards:

- Superior fire resistance, with the ability to withstand direct flame without combustion

- Excellent moisture resistance and dimensional stability

- High strength-to-weight ratio for easier handling and installation

- Resistance to mold, mildew, and insects

- Eco-friendly composition without toxic additives

What is magnesium oxide contributing to modern construction practices? Beyond MgO boards, it serves as a critical ingredient in specialized cements and mortars. Magnesium oxychloride cement (also called Sorel cement) and magnesium phosphate cement offer rapid setting times, exceptional bonding strength, and improved durability compared to conventional Portland cement in certain applications.

For construction material manufacturers, magnesium oxide provides opportunities to develop premium products with enhanced performance characteristics. These materials address growing market demands for fire safety, moisture management, and sustainable building solutions—priorities that align with evolving building codes and consumer preferences.

Environmental Applications: Ecological Problem-Solver

In an era of increasing environmental consciousness, magnesium oxide has emerged as a valuable tool for addressing ecological challenges. Its alkaline nature makes it particularly effective for:

- Neutralizing acidic waste in industrial processes

- Treating wastewater to remove heavy metals and adjust pH

- Remediating soil contaminated with acidic compounds

- Capturing certain air pollutants in emission control systems

What is magnesium oxide’s mechanism in environmental applications? When introduced to acidic environments, it readily reacts to neutralize acids, forming magnesium salts and water. This simple chemical process has profound implications for waste management and environmental protection.

For example, in mining operations where acid mine drainage threatens local water sources, magnesium oxide can be deployed as part of a comprehensive treatment strategy. Similarly, industrial facilities that generate acidic waste streams can use MgO to treat effluent before discharge, ensuring compliance with environmental regulations while protecting aquatic ecosystems.

The growing focus on sustainable industrial practices has increased demand for effective, environmentally compatible treatment solutions—a need that magnesium oxide helps fulfill through its natural composition and reactive properties.

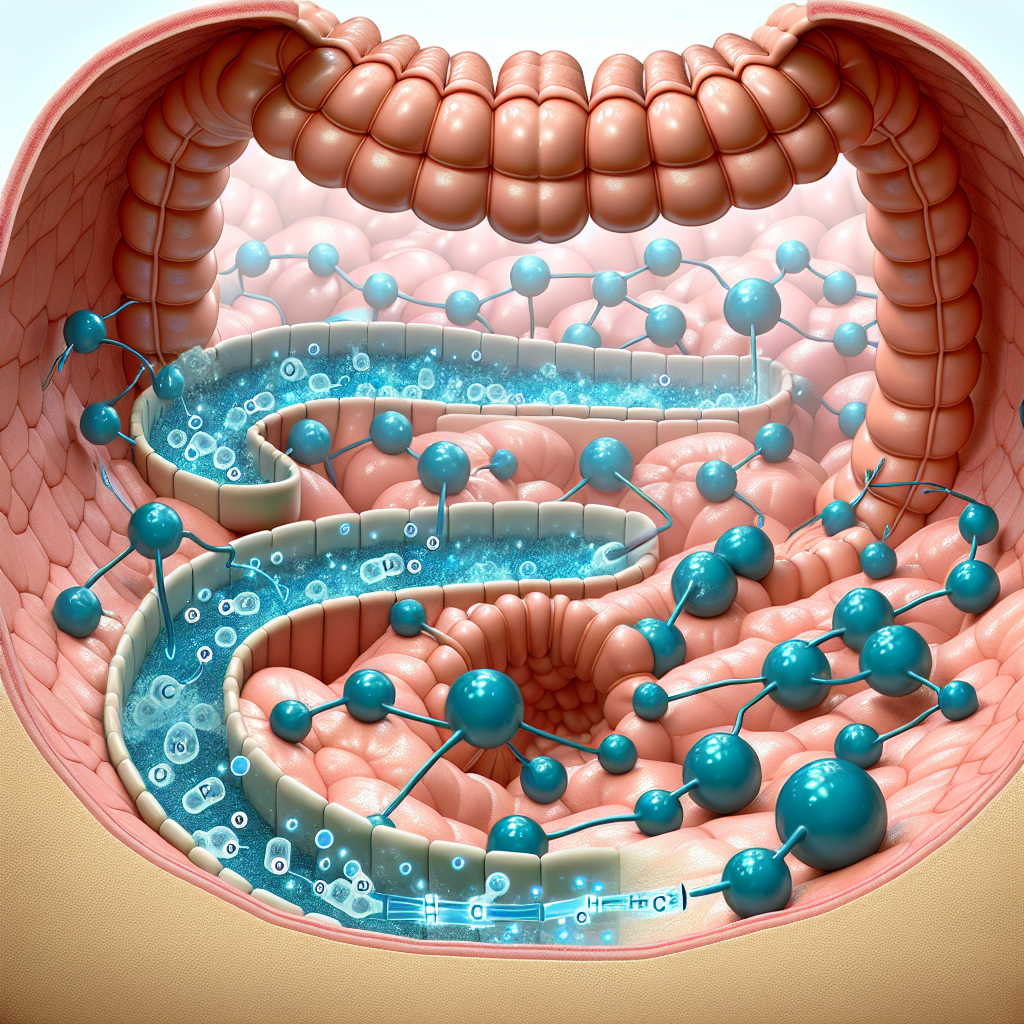

Food Processing and Nutritional Applications: Supporting Health

Beyond its industrial applications, magnesium oxide plays a significant role in the food processing industry and nutritional supplement sector. In food processing, it serves as:

- An anti-caking agent to maintain product quality

- A color retention agent in certain applications

- A neutralizing agent for excess acidity

- A nutrient fortification ingredient

What is magnesium oxide’s most recognized role in nutrition? It serves as a concentrated source of elemental magnesium, an essential mineral that supports over 300 biochemical reactions in the human body. Nutritional product developers utilize magnesium oxide in supplement formulations for several reasons:

- High magnesium content (approximately 60% elemental magnesium by weight)

- Cost-effective delivery of this essential mineral

- Stability and long shelf life

- Versatility in various formulation types

While some debate exists regarding its bioavailability compared to other magnesium forms, magnesium oxide remains one of the most commonly used sources of supplemental magnesium. Health-conscious product manufacturers continue to include it in multivitamin formulations, specialized magnesium supplements, and functional foods designed to address the widespread magnesium deficiency in modern diets.

For companies in the nutritional space, understanding the properties and appropriate applications of magnesium oxide enables the development of effective, science-backed products that meet consumer health needs.

Thermal Applications: Heating with Precision

The exceptional thermal properties of magnesium oxide make it valuable in specialized heating applications. Its high thermal conductivity coupled with electrical insulating properties creates a unique combination for:

- Heating elements in industrial furnaces

- Insulated conductor cables for high-temperature environments

- Thermocouple insulation tubes

- Heat transfer compounds

What is magnesium oxide contributing to these thermal applications? It effectively transfers heat while preventing electrical current flow—a critical combination for safe, efficient heating systems. In applications where both heat and electricity are present, MgO provides the necessary barrier between conductive elements while facilitating thermal transfer.

For manufacturers of heating equipment and systems, magnesium oxide offers a reliable material solution that enhances product performance and safety. As energy efficiency becomes increasingly important across industries, materials that optimize thermal management will continue growing in relevance.

Electronic and Specialty Applications: Enabling Advanced Technologies

In the rapidly evolving world of electronics and specialty materials, magnesium oxide fulfills niche but crucial roles:

- Substrate material for thin-film circuits

- Insulating component in power semiconductor devices

- Protective coating for specialized electronic applications

- Optical material for certain specialized lenses and windows

What is magnesium oxide bringing to these advanced applications? Its combination of electrical insulation, thermal conductivity, and stability at high temperatures makes it suitable for environments where conventional materials would fail. Additionally, high-purity magnesium oxide exhibits useful optical properties for specialized applications in research and industrial settings.

While these applications represent smaller volume uses compared to refractories or construction materials, they highlight the remarkable versatility of magnesium oxide across the technology spectrum. For R&D companies and specialty manufacturers, this mineral provides unique material solutions for challenging technical requirements.

The Future of Magnesium Oxide: Innovation and Opportunity

As we look toward the future, magnesium oxide is positioned to play an increasingly important role across industries. Ongoing research continues to uncover new applications and refine existing ones, driven by:

- Demand for more sustainable and environmentally friendly materials

- Need for materials that perform reliably under extreme conditions

- Growing focus on resource efficiency and circular economy principles

- Increasing recognition of magnesium’s importance in human health

What is magnesium oxide’s potential in emerging technologies? Researchers are exploring its use in advanced energy storage systems, carbon capture technologies, and next-generation building materials. These innovations build upon the fundamental properties that have made magnesium oxide valuable for generations while addressing contemporary challenges.

For businesses across the industrial spectrum, from construction to health, understanding the capabilities and applications of magnesium oxide creates opportunities for product innovation, process improvement, and competitive differentiation. This mighty mineral’s versatility makes it relevant to nearly any industry where material performance matters.

In alignment with our philosophy of quality, transparency, and empowerment, recognizing the true value of materials like magnesium oxide enables better decision-making and more effective product development. Whether you’re developing nutritional supplements, manufacturing industrial equipment, or creating sustainable building materials, magnesium oxide offers proven performance with continuing potential for innovation.

From withstanding the extreme heat of industrial furnaces to providing essential nutrients in health supplements, magnesium oxide truly stands as a mighty mineral with remarkable versatility and enduring relevance across diverse industries.