In the ever-evolving landscape of nutritional supplements, essential amino acids (EAAs) have emerged as a transformative force reshaping manufacturing quality standards worldwide. As we approach 2025, the spotlight on EAAs continues to intensify, with market projections indicating that essential amino acids will account for 58.5% of product-level demand in the amino acid sector. This surge reflects not just growing consumer interest, but a fundamental shift in how manufacturers approach product development, quality assurance, and regulatory compliance.

Essential amino acids represent the cornerstone of protein nutrition—the building blocks that our bodies cannot produce independently yet require for countless physiological functions. Their critical role in human health has prompted supplement manufacturers to elevate production standards, embracing advanced biotechnologies and automation that promise to revolutionize the industry by 2025.

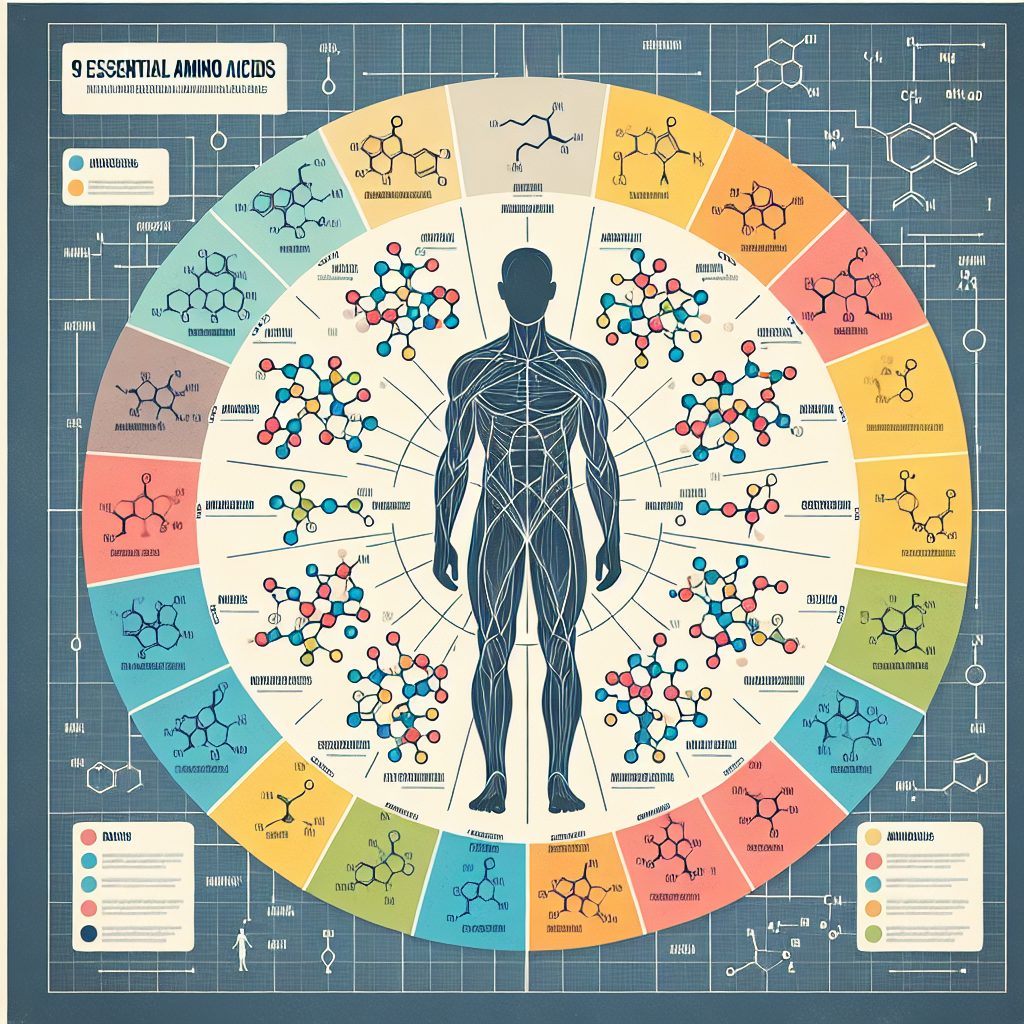

Understanding Essential Amino Acids: The Foundation of Quality Nutrition

Essential amino acids are the nine amino acids that the human body cannot synthesize on its own, making them “essential” components of our diet. These include histidine, isoleucine, leucine, lysine, methionine, phenylalanine, threonine, tryptophan, and valine. Each plays a distinct and vital role in maintaining optimal health and physiological function.

For supplement manufacturers, understanding these components is critical to developing effective products:

Leucine stands as perhaps the most celebrated EAA, functioning as a primary trigger for muscle protein synthesis through the activation of the mTOR pathway—a crucial consideration for sports nutrition manufacturers.

Isoleucine and Valine, together with leucine, form the branched-chain amino acids (BCAAs) group, supporting energy production during exercise and promoting recovery—essential qualities for performance-focused supplements.

Lysine contributes to collagen formation, making it valuable for skin health products and joint support formulations.

Tryptophan serves as a precursor to serotonin, positioning it as a key ingredient in sleep and mood enhancement supplements.

Phenylalanine plays a role in the production of other amino acids and various neurotransmitters that regulate mood.

Methionine functions as an antioxidant and is crucial for detoxification processes, adding value to liver support formulations.

Threonine is essential for immune function and the production of antibodies.

Histidine supports nerve signal transmission and is vital for maintaining the myelin sheath.

Forward-thinking manufacturers recognize that a complete profile of all nine essential amino acids delivers superior results compared to isolated amino acid products. This comprehensive approach is increasingly becoming the industry standard for 2025, as research consistently demonstrates the synergistic benefits of complete EAA formulations.

The Manufacturing Benefits of Essential Amino Acids

The incorporation of essential amino acids into product formulations offers manufacturers numerous advantages in meeting evolving consumer demands. The global essential amino acid market is projected to reach $7.89 billion by 2033, growing at a CAGR of 6.9% from 2026. This growth is driven by multiple benefits:

Nutritional Superiority

EAAs provide comprehensive nutritional support for multiple bodily functions. Unlike incomplete protein sources, products containing all nine essential amino acids deliver balanced nutrition that supports muscle maintenance, immune function, neurotransmitter production, and overall metabolic health.

Versatility in Applications

Essential amino acids offer remarkable versatility across product categories. From sports nutrition and weight management to healthy aging and cognitive support, EAAs can enhance various formulations, allowing manufacturers to diversify their product offerings while maintaining a consistent quality standard.

Plant-Based Opportunity

With the rising demand for plant-based nutrition, essential amino acids present a significant opportunity for manufacturers. By strategically combining different plant sources or incorporating purified EAAs, companies can overcome the limitations of individual plant proteins, which often lack one or more essential amino acids.

For nutritional product developers, this represents a chance to create plant-based formulations that rival animal proteins in their amino acid completeness—a key consideration as the market continues to shift toward sustainable and plant-forward options.

Quality-Focused Supplementation Guidelines for Manufacturers

As manufacturers develop EAA-based products, establishing clear supplementation guidelines becomes essential for ensuring consumer satisfaction and product efficacy:

Dosage Precision

Research indicates that approximately 10 grams of essential amino acids effectively stimulates muscle protein synthesis when consumed during or immediately following exercise. This precise dosing should be clearly communicated on product labels, along with usage instructions that maximize absorption and utilization.

Timing Strategies

Product development should consider the timing of EAA consumption for optimal results. Morning supplementation may support metabolic health, while pre-workout formulations can enhance performance and post-workout products accelerate recovery. This creates opportunities for specialized product lines addressing different consumption occasions.

Formulation Balance

The ratio of individual amino acids in a formulation significantly impacts its effectiveness. While leucine plays a prominent role in triggering protein synthesis (typically recommended at 2-3 grams per serving), a balanced profile of all nine EAAs delivers superior results. This balanced approach should be highlighted in product messaging to differentiate from less complete alternatives.

Health-conscious product manufacturers that address these considerations in their formulation strategy will be well-positioned to capture market share in the growing EAA sector.

Essential Quality Factors in Manufacturing EAAs

As the essential amino acid market expands, quality assurance becomes increasingly critical. By 2025, several factors will define manufacturing excellence in this sector:

Good Manufacturing Practices (GMP)

Adherence to GMP standards represents the baseline for quality in EAA production. These practices ensure consistent product quality through documented procedures, trained personnel, suitable facilities, and robust quality control systems. Manufacturers must implement:

– Detailed standard operating procedures (SOPs)

– Regular employee training and qualification

– Validated cleaning protocols to prevent cross-contamination

– Comprehensive batch documentation and traceability

The implementation of these practices is non-negotiable for manufacturers aiming to meet the industry’s rising quality expectations.

Third-Party Testing and Verification

Independent verification has become essential for building consumer trust. Third-party testing by organizations like NSF, USP, or Informed Choice provides objective confirmation of:

– Ingredient identity and potency

– Absence of contaminants and prohibited substances

– Label claim accuracy

– Manufacturing process compliance

This verification process becomes particularly important as the market becomes more competitive, allowing quality-focused manufacturers to differentiate their products with credible certification marks.

Advanced Analytical Technologies

The implementation of cutting-edge analytical methods enables manufacturers to achieve unprecedented levels of quality control:

– High-performance liquid chromatography (HPLC) for amino acid profile verification

– Mass spectrometry for detecting contaminants at parts-per-billion levels

– Near-infrared spectroscopy for rapid in-process testing

– DNA barcoding for authenticating biological sources

These technologies allow for precise quality control throughout the manufacturing process, ensuring that the final product delivers the promised essential amino acid profile.

Supply Chain Transparency

By 2025, complete supply chain visibility will be standard practice for leading EAA manufacturers. This includes:

– Detailed documentation of raw material sourcing

– Supplier qualification and ongoing assessment

– Traceability from source to finished product

– Environmental and ethical production considerations

This transparency not only supports quality assurance but also addresses growing consumer demand for ethically sourced and sustainably produced supplements.

Addressing Safety Considerations in EAA Manufacturing

While essential amino acids offer significant benefits, responsible manufacturers must address potential risks associated with supplementation:

Individual Tolerance Considerations

Product labeling should acknowledge that individual responses to EAA supplementation may vary. Manufacturers should recommend starting with lower doses to assess tolerance, particularly for consumers new to amino acid supplementation.

Interaction Awareness

Product information should note potential interactions between EAAs and certain medications, particularly for lysine, which may interact with aminoglycoside antibiotics, and tryptophan, which may affect serotonergic medications.

Special Population Guidance

Manufacturers should provide specific guidance for special populations, including:

– Pregnant or nursing women

– Individuals with pre-existing health conditions, particularly kidney or liver impairment

– Elderly consumers with altered protein metabolism

– Young athletes with different nutritional needs than adults

These safety considerations should be integrated into both product formulation and consumer education materials, demonstrating the manufacturer’s commitment to consumer wellbeing beyond sales.

The NutraAeon Approach: Setting the Standard for EAA Excellence

As the essential amino acid market continues to evolve, NutraAeon stands as a trusted global partner helping manufacturers navigate this dynamic landscape. Our philosophy of quality, transparency, and empowerment aligns perfectly with the direction of the EAA sector, positioning us to support forward-thinking manufacturers in several key ways:

Rigorous Quality Standards

At NutraAeon, we implement industry-leading testing protocols that exceed USP and FDA expectations for our amino acid series. Each batch undergoes comprehensive analysis to verify identity, potency, and purity before reaching our manufacturing partners.

Complete Documentation

We provide complete certificates of analysis, stability data, and full supply chain visibility for all our essential amino acids, supporting manufacturers in their quality assurance processes and regulatory compliance efforts.

Technical Expertise

Our team offers specialized formulation support, helping product developers optimize their EAA profiles for specific applications and consumer needs. This technical partnership goes beyond mere ingredient supply, enabling innovative product development.

Market Insights

By staying at the forefront of amino acid research and market trends, NutraAeon helps manufacturing partners anticipate consumer needs and regulatory changes, creating products that will remain competitive in the 2025 landscape and beyond.

As we look toward 2025, the essential amino acid sector will continue to set new standards for manufacturing excellence. The companies that embrace comprehensive quality assurance, transparent sourcing, and evidence-based formulation will lead this evolution, delivering products that truly support consumer health while meeting increasingly rigorous regulatory requirements.

Through our commitment to exceptional quality and service, NutraAeon remains dedicated to empowering health-conscious product manufacturers with the premium nutritional ingredients needed to excel in this competitive market. By partnering with forward-thinking companies, we continue to advance the standard of excellence in essential amino acid production, supporting innovations that will define the supplement industry for years to come.